Welcome to your new PC gaming obsession: artisan keycaps

Take your PC aesthetic to the next level.

If you aren't already a convert to the wonderful world of artisan keycaps, I promise you will be. There's nothing PC gamers love more than personalising their setups—except maybe one-shotting me in Hunt: Showdown—and honing in on a particular piece of hardware or peripheral to see how it could be made your own is as much a part of the hobby for many as playing games.

Artisan keycaps are far from your usual hunk of square-ish functional plastic. They're not always intended to be practical, nor a replacement for your everyday set (although some people will do that at great expense). They can be a linchpin for a PC build aesthetic, a nod to your favourite game or character, an embodiment of a mood or location, and art worthy of your admiration.

They can just as often be comical or silly as they are stunning and beautiful.

I've bought just a few in my time, namely two koi pond designs from Jelly Key. Of all the PC hardware I've amassed over the years, though, it's these two keycaps that I take most pristine care of. I've ripped apart $1,000+ graphics cards yet more carefully fitted these keycaps back inside their cute wooden boxes.

It would be my pleasure to tell you all about how the humble keycap has spawned an entire community of hobbyists and businesses, but sparing you that lecture with my own words, I've instead spoken with experts and well-known artisan extraordinaire to dive into what makes artisan keycaps something truly special, why the business is taking off, and even how to go about making some yourself.

The business side

The business of artisan keycaps

Robert Vignone, CEO of artisan keycap maker Clackeys, and Max Cohen jumped on a call with me to talk about their growing business of artisan keycaps. They're based out of Davis, California, which is where all of their keycaps are designed, manufactured, and shipped.

Clackeys creates stunning keycaps, a great deal of which will be instantly recognisable to gamers. There's one in the style of Overwatch's Widowmaker, another a Stormtrooper's mask blown to bits, exposing the skull beneath. There's a cacodemon, a necronomicon (my personal favourite), an astronaut, and many more.

The biggest gaming news, reviews and hardware deals

Keep up to date with the most important stories and the best deals, as picked by the PC Gamer team.

Designing the keys comes as second nature to Vignone, an ex-Dreamworks animator. His experience in 3D modelling and 3D printing seemed a good fit for the then much more niche world of artisan keycaps, and it was only one test run later before "it just blew up, basically."

"I had an Etsy store at that time. And I basically accidentally started a company," Vignone tells me.

"So once I did one keycap it was pretty successful. I was like, 'Okay, I'm gonna make more stuff.' And then because my background is in entertainment, and games and movies, I've always kind of focused on working in that style, or in that fan art kind of way. We started in 2016. At the end of the year, I think November, December. And yeah, and here we are today, growing even through a pandemic, we're growing."

Vignone and Cohen are the first to admit that the coronavirus pandemic has seen an increased interest in making your own at-home PC setup somewhere nice to be all day, and therefore is partially responsible for a rise in interest in keycaps alongside it.

"I think that with COVID, everybody's spending more time at home working on their workplace," Cohen tells me. "People care more if they have a standing desk at home. Now, people want to make sure that their computer is as good if not better than the work computer, so they can accomplish all of their tasks without any issues or whatever. And all of that being put together, everyone's like, 'I want to make it feel like my own, individual and customised'.

And there's a lot that even a diminutive keycap can do to making something feel your own, or special. And making the most of that small size and stature, while maintaining detail and flourishes, is something that Clackeys prides itself on.

It's not just about making one really good one, it's about making like hundreds and maybe 1000s of that one design.

Robert Vignone, CEO of Clackeys

"We kind of take a nod or note from miniatures in general, where you just learn to like exaggerate certain things," Vignone explains. "Since we're hand painting everything you learn to exaggerate certain details, so that way you can actually paint it easier."

"It's not just about making one really good one, it's about making like hundreds and maybe 1000s of that one design."

It's also about striking the right balance between complexity and simplicity, and keeping that essence of the source material in mind, whether that be a game or movie, cult classic, or flash-in-the-pan internet trend.

The process can take Clackeys mere days to complete, from design to prototyping, all the way to final production key. The inherent flexibility of doing everything in-house, even manufacturing—thanks to 3D printing technology—is something of a feather in Clackeys' cap.

"Say you're trying to get a plastic toy like Funko printed in Asia," Cohen says, "like you have 30 grand tooling costs for that singular toy. For us, we just hit Ctrl-P, go to a resin printer, and we can turn it around in two days. So yeah, it's really cool when there are big, new exciting things. We can test it out before we even offer the idea to the customer of say like, 'hey, this might work, this might not work.' But we can do it in house before dropping a lot of money or dropping a lot of resources."

"There's definitely been past products where I'd wake up Tuesday morning, I design something and Wednesday morning, it's up for sale," Vignone continues. "That's the ZBrush design. That's the prototype print. That's the prototype paint job, and testing to make sure that it fits well and looks good at different angles. And then it's ready to go."

From there it's off to printing, and Clackeys can make up to 120 keycaps per day. Most of which requires careful painting.

Using a 3D printer—specifically a resin printer that uses a vat of resin and a UV panel to allow for complex, minute details—was not the standard approach to making keycaps when Clackeys opened its doors. That's resin casting, a slightly more stage-heavy approach which relies on custom moulds and careful masters to instil that artisan magic.

Such was the difference between the two approaches to bespoke keycap designs that Cohen and Vignone remember the days when they felt on the periphery of artisan keycaps, looking in.

"We were talking about this the other day when Robert first started," Cohen explains, "he said to me over lunch that 3D-printed key caps were not considered artisans. And it's crazy to think that that was a very common then but has completely done a 180 since."

"I think I was considered like an outcast of the artists and maker community at the time." Vignone says.

That opinion has notably changed in the eyes of many, however, as Clackeys has swiftly risen to become a well-known company in the design and manufacturing of artisan keycaps.

Rightfully so, too. The latest design from Clackeys is an astronaut with a separate visor that swings away to reveal a moon or sparkling nebula.

"This is five parts, plus the visor comes out, and it has a hinge system on it," Vignone explains. "I did this for two reasons. One, if anybody ever breaks their artisan, the part that is like probably most breakable is the part that moves, I can send them a new one. So that is the big one for us: trying to limit accidents, basically. And then the second is making it more manufacturable here, because we produce and manufacture everything in-house nothing that we do is mass-made overseas."

From the outside, it appears as though artisan keycaps are gaining popularity at a rapid pace, but it's something I want to get an insider perspective on. I ask Vignone where he sees the company in one, maybe two, years, and it's clear Clackeys has serious expansion planned.

"A bigger office would be nice." Vignone laughs. "I think you know what, right now we're kind of a two to six personnel team. And then I would say, in two years, I would like to be a 10 to 15 person team, maybe 20 max. And I think that would be like the perfect size to accommodate some of the bigger projects that we have lined up."

While Vignone and Cohen won't say exactly what they have planned for Clackeys going forward, they want the business to exist across three major categories: working with famed keycap specialists, such as GMK, a German manufacturer of custom board keycap sets; widening their brief to work with bigger companies beyond keycaps; and, of course, even more bespoke artisan designs.

"That'll be really, really exciting," Cohen says.

Make your own

The hobby of artisan keycaps

For a dive into the hobby of making artisan keycaps, we're speaking with Glenn Black, part-hobbyist, part-professional artisan keycap maker extraordinaire living in San Francisco.

Black is not shy to 3D printing by any measure, but when it comes to keycaps, Black prefers to utilise it for the manufacturing of the tools required to make keycaps, not the keycaps themselves. Rather, Black uses a method of tinkering and perfecting resin moulds for his keys, known as resin casting.

It must be said that there's no divide between business and hobby along manufacturing lines, only differing approaches to similar ends. You'll hear plenty of kind words said about the alternative from both Vignone and Black, too. There are similarly many businesses making keycaps using resin casting, and hobbyists choosing a 3D printer. You could even use a mix of both, if you're savvy enough.

It just so happens Black offers us an insight into the flip side of the artisan crafting coin. That's ideal, too, as to talk about artisan keycaps without mention of resin casting would be something of a disservice.

When it comes to resin casting, as a budding beginner myself, and with no experience 3D printing at that time, it was my first port of call when I first investigated how to go about making my very own keycaps. That's also where I first came across Black's work.

Black, who goes by the username The Glyph, produced a handful of videos with fellow keycap maker and friend, AuthenticDanger, for the Artisan Alliance YouTube channel. Their top hit, a video explaining the basics of resin casting and the tools required, is still very useful for today if you require a breakdown of how resin casting works.

And to my luck, Black is still creating keycaps and remains just as passionate about them, alongside his full-time work and countless other hobbies.

"My general personal mission statement is to make everything I want that I can't buy," Black tells me. "Whatever method of fabrication that is. To me, finding a design vision of this thing that you want to exist and then being told you can't have that because no one else decided to make it for you is just not a way that I want to live life."

An interest in artisan keycaps would eventually come out of that mission.

"I'd always wanted to do resin casting, and it always been really overwhelmed by just how massive of like there's infinite different polymers out there. And they all have little specs and you don't know which one and why some are toxic, and some are just like way too much to ever get into it."

Lucky for you, dear reader, there is plenty of information already collated out there to keep you away from the toxic stuff (although you should take care no matter the resin). In Black's case, however, it was a case of one thing leading to another: a drive for creating his own things, to get to grips with resin casting, and a growing interest in the world of mechanical keyboards.

I just kind of figured, here we go. I'll abandoned it at any time if it's not fun, and then it got pretty fun pretty fast.

Glenn Black

"When I was kind of getting into keyboards a bit more just because I cared about the tactile field, like I work in gaming and stuff, so it always made sense to me, like this input device should feel good. And then discovering the world of mechanical keyboards, where they also get aesthetics and all that stuff. I was like, 'Oh, this is pretty cool.' And then just being near to that for long enough, and like seeing a bunch of other artisans that were either cool or not cool, that either inspired me or inspired me to do better, whatever that was. I just wanted to start kind of dabbling in it.

"I just kind of figured, here we go. I'll abandoned it at any time if it's not fun, and then it got pretty fun pretty fast."

Let's breakdown what it actually means to build a keycap from scratch with the resin casting method.

The list of tools and materials required is lengthy, it must be said. You'll need a pressure pot (degassing chamber), silicone, resin, mould release sprays, a keycap or two, syringes, and all manner of smaller tools to fine tune your art. If you're planning to build up a master key out of clay, or any other medium for that matter, you'll require all you need for manipulating and preparing that, too.

I highly recommend you check out the materials list in the Artisan Alliance video embedded below for the finer details.

As Black puts it, you're creating a two-part mould: the aesthetic top section, where your artistic design lives; and the bottom section, the interface to allow the keycap to function with your keyboard of choice.

So you need a moulding system that allows to both mould the top, bottom, and do so in a repeatable manner. That last part is, mind the pun, key.

"So the first thing you have to do is create your top mould. You find whatever master keycap you want, whether that's a sculpted master or an off the shelf blank or a blob of clay, doesn't really matter. But you would have to create the top mould for that using some kind of a box so that your silicone doesn't flow everywhere.

"And then you would need to essentially flip it over and cast the bottom mould. And then you can add, you know, you have to add sprue systems to allow resin to flow. There's a lot of little details there. But the essence is just get your master get the top, flip it over, get the bottom and then you can now cast copies of keycap using those two moulds."

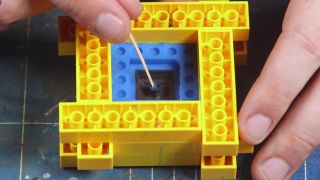

It's a relatively simple concept, if one that's not quite as easy in practice. And one that's even harder to master. But Black holds that for the right person, with enough dedication, and enough Lego pieces, you could also find the excitement for resin casting that has kept him hooked.

You read that right.

There are tools to make the resin casting process simpler. Some of which, the L2K adapters, are of Black's own design. And others which are nostalgic childhood favourites.

"L2K is a simple adapter for interfacing keycaps to Legos. Basically, Legos, we think of them as toys from childhood. But the mechanical properties of them are pretty insane. Like the spec, you know, you put a million different bricks down, and they will almost all be within like a couple thousandths of an inch of each other. Like they're just extremely precise for being cheap toys.

"So they're actually a really useful tool in mold making that a lot of people have used for a long time just for making the box walls because you have to have a box bigger than your part in order to cast the mould that just contains silicone in it."

To keep the master aligned when creating the silicone mold for both top and bottom pieces, and with enough accuracy, Black created the L2K adapters.

"So the L2K snaps to a Lego brick and then has a stem on it. So when you place a keycap there, it will always be in the exact same place in the box. And that means I can make 10 top molds and 10 bottom molds separately, but they'll always fit together perfectly."

You can find Black's L2K adapters over on The Glyph Shop, while GTB Labs lists even more of his work, including the wonderful Crux Cap and some custom controllers.

As Black explains, the fundamental process of resin casting a keycap is one of constant tweaks and changes. It's just as much a learning process, too, as you'll find complexity in design comes from challenging yourself or trying to stay true to that vision of the finished product as it is in your mind's eye.

"The first key cap that I really did, and the one that got me the most excited about keycaps. was the crux cap," Black says. "…and the idea of the crux cap was like, if I had this up on my board, and someone walked by it, they would be like, 'Oh, you like keyboards? Oh, wait, do you also climb?' and I'd be like, 'yeah, I climb because look at this little climbing wall on my keyboard.' Just this way to stay completely within art, like you're not compromising any part of the artisan experience of it, but you're also showcasing this climbing wall, was just a really beautiful mashup to me."

Just how easy is it to design and create your own artisan keycaps then? Black says it ultimately comes down to your mentality.

"I differentiate things as being difficult and being tedious." Black explains. "Difficult implies that there's some concept that you have to figure out. And until you figure that out, you can't get there. Keycaps, in that comparison, are tedium.

"Like there's nothing about it that is ultimately hard to solve. However, there's just an immense amount of little things that just take time to get through. And, you know, now the availability of casting technology has dramatically reduced that tedium. And that was kind of the point for at least for the Artisan Alliance. But there's still a lot of it, like, you're just going to cast bad stuff until you cast better stuff. And then you can continue to always cast better and better stuff. So in that sense, it's super accessible. But it can also be super frustrating."

Undoubtedly, then, manufacturing your own keycaps is a niche hobby. As Black puts it: "a niche hobby, in a niche hobby, in a niche hobby." But one that can be highly rewarding if you're prepared to put the effort into it.

From a humble hobby to a business on the side, to a larger-scale operation like Clackeys, though, there's a laundry list of reasons why artisan keycaps could become your next PC gaming obsession. Even if you're more than happy to let someone else do all the hard work and wish to donate your hard earned cash in pursuit of becoming a keycap connoisseur.

Come, join us...

This article was first published in March 2021, but y'know, artisan keycaps are always cool.

Jacob earned his first byline writing for his own tech blog. From there, he graduated to professionally breaking things as hardware writer at PCGamesN, and would go on to run the team as hardware editor. He joined PC Gamer's top staff as senior hardware editor before becoming managing editor of the hardware team, and you'll now find him reporting on the latest developments in the technology and gaming industries and testing the newest PC components.

Most Popular